Thermoforming Service Manufacturing Process Custom Plastic Product Vacuum Forming

Description

Basic Info.

| Model NO. | ZC-P028 |

| Specification | As according to customers′ request. |

| Trademark | ZUCOO |

| Origin | China |

| Production Capacity | 100000 PCS |

Product Description

Product Description | ODM plastic injection molding |

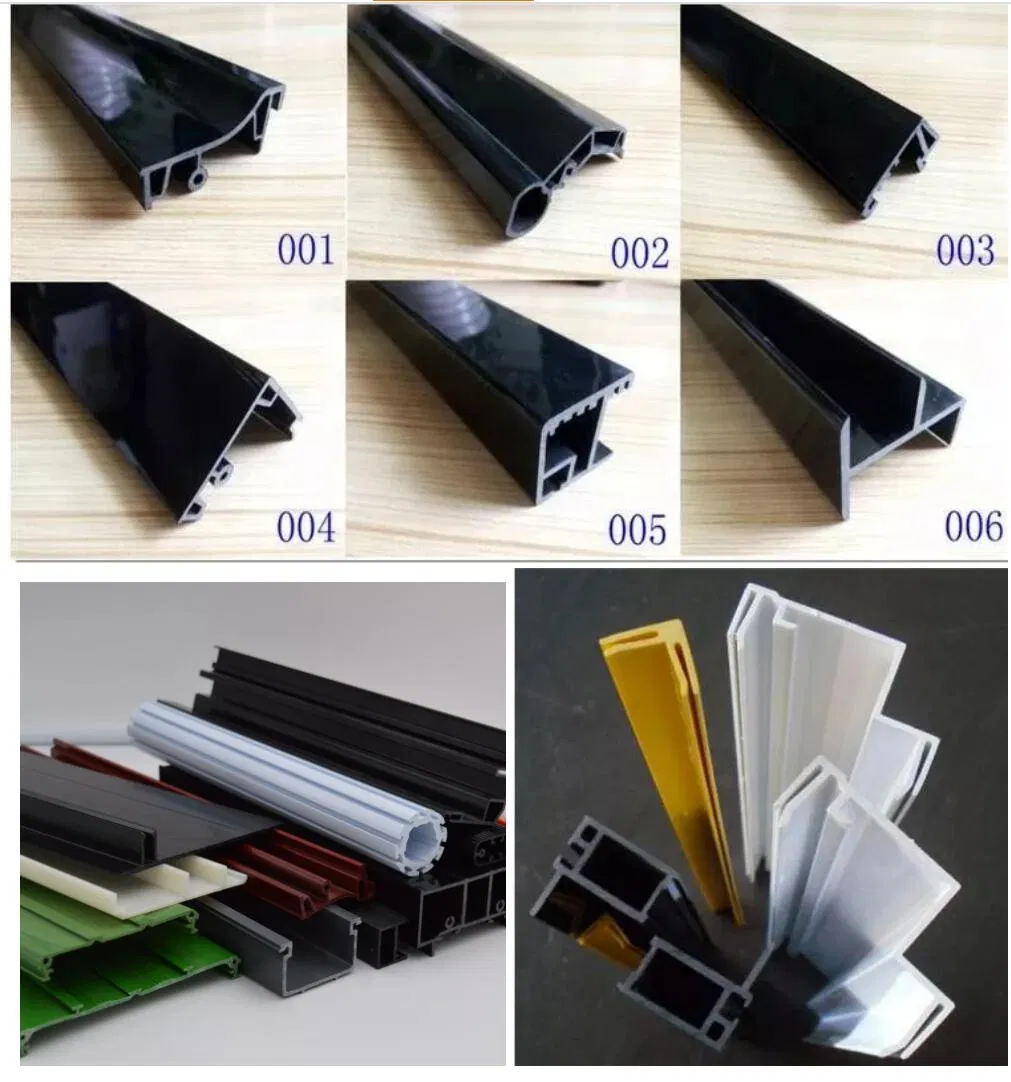

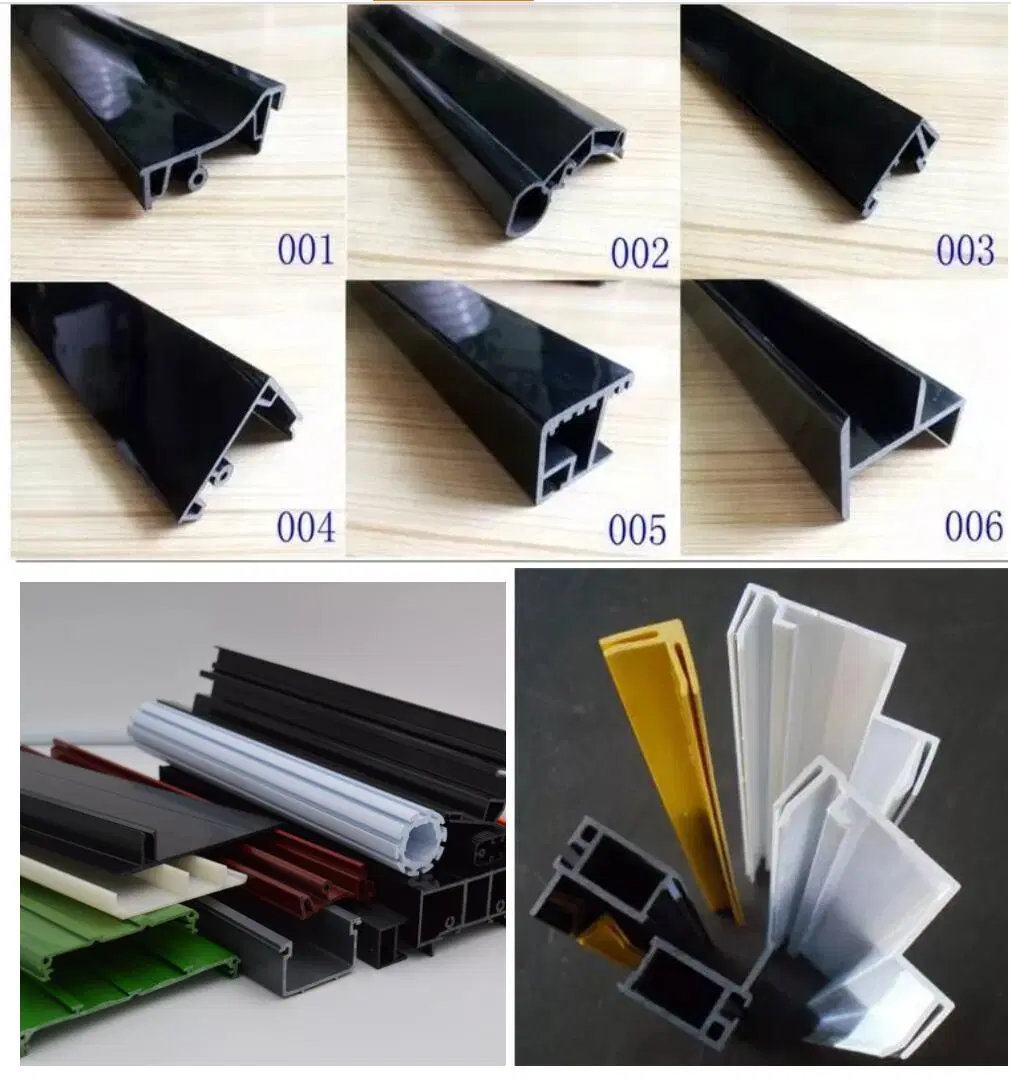

Plastic Materials: | PS, ABS, PP, PVC, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

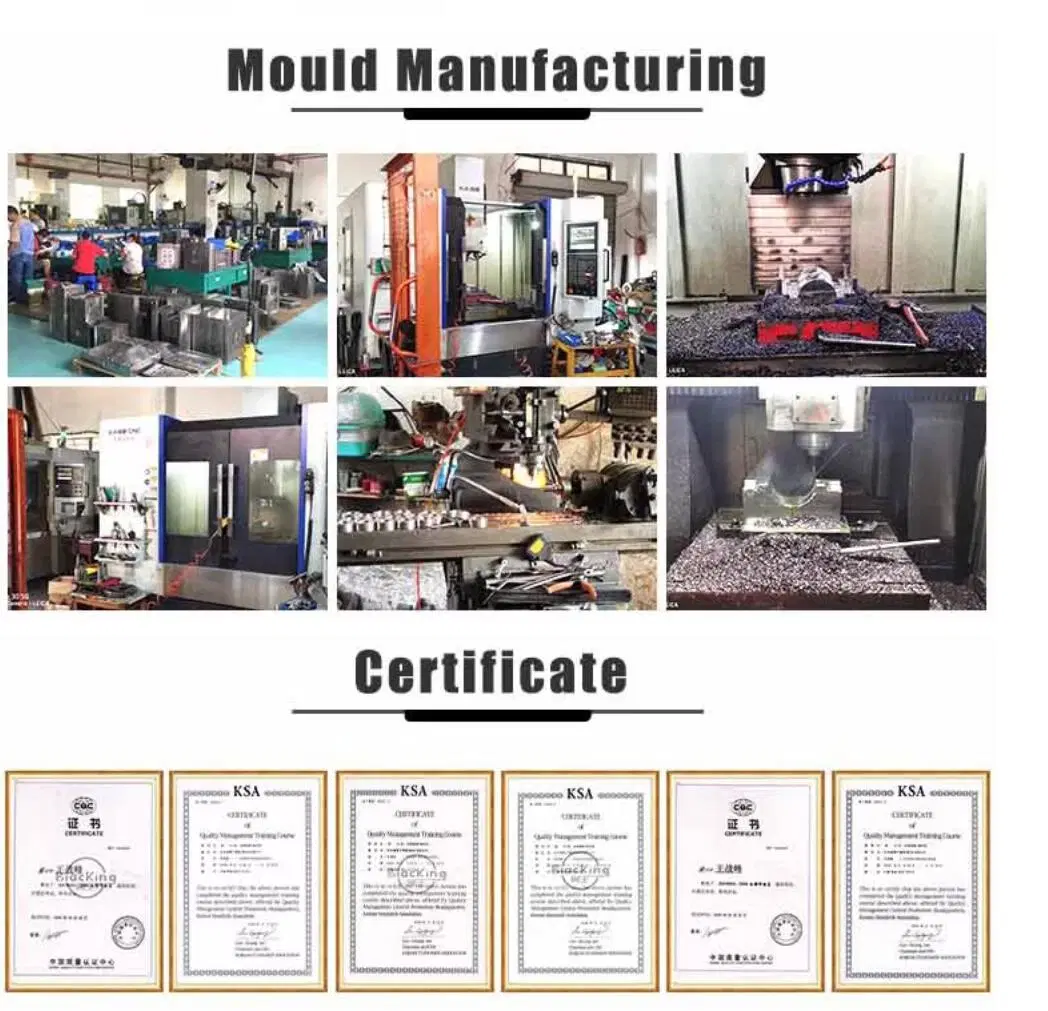

Standard: | ISO9001:2008 |

Other materials: | Rubber, Slilconce rubber,Aluminum, Zinc,Copper...Metal...etc. |

Quality: | RoSH and SGS standard |

Feature: | Non marking and Non flash |

Size: | According to your 2D, 3D Drawing |

To be discussed | Color,Quantity,Unit price,Tooling cost,Tooling size: |

Package: | Standard exported Wooden box packed, Fumigation process(upon required) |

Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

Export Country: | Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

Experience: | experience in plastic injection mold making and plastic prouducts produce. |

To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold,Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

Mould Base: | Hasco Standard, European Standard, World Standard |

Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

Surface Finish: | Texture(MT standard), High gloss polishing |

Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

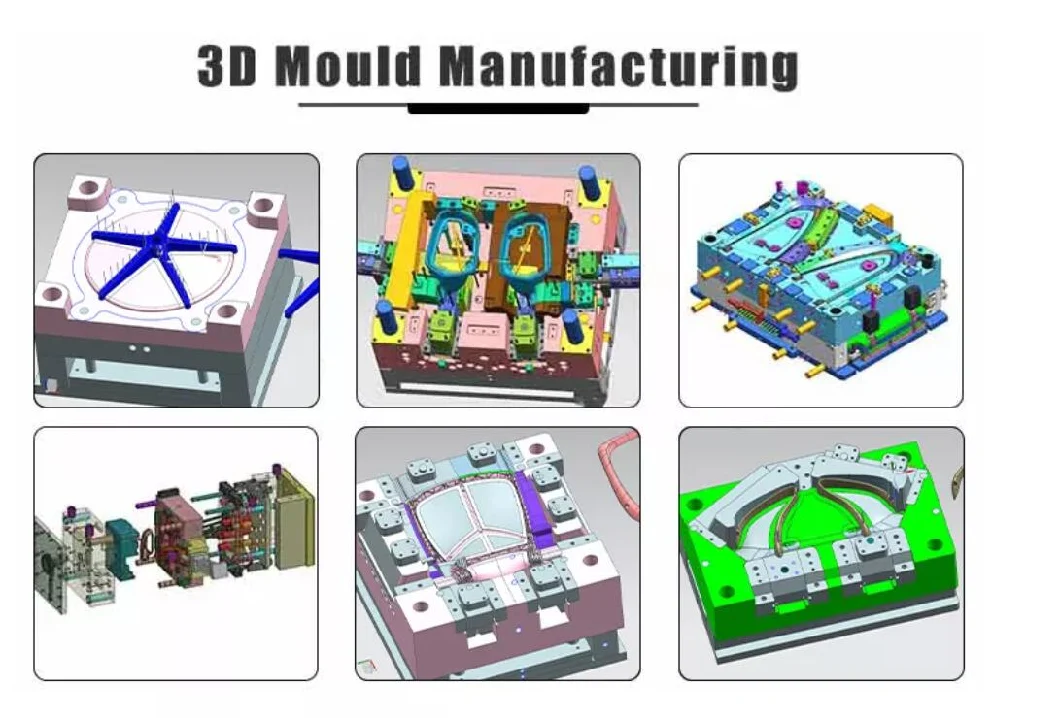

Design & Program Softwares: | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

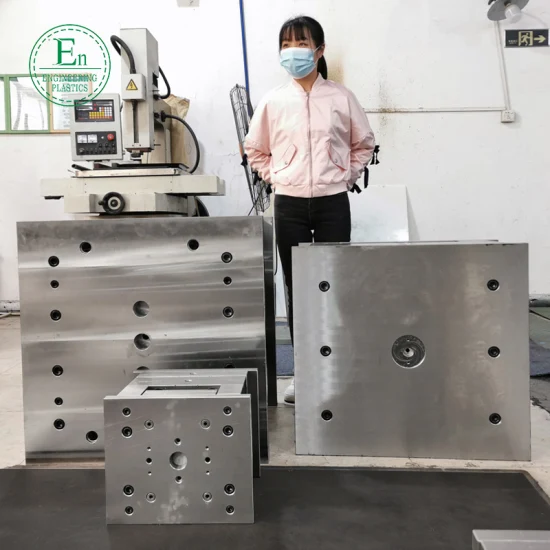

Equipments: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000Tavailable. |

Prev: Thermoforming Pet Furniture Recycled Pet Felt Cat House Travel Pet Products with Blanket

Next: Zs

Our Contact